Below is a 1000-word SEO-optimized post with simple ASCII-style diagrams and a conceptual graph that can be embedded directly into a blog. If you want these converted into high-resolution images later, I can generate them.

- 1. Understanding the Project Architecture

- 2. Designing the Omni-Directional Base

- 3. Building the Programmable Robotic Arm

- 4. Required Components

- 5. Programming the Omni-Directional Drive System

- 6. Programming the Robotic Arm

- 7. Integrating the Systems

- 8. Example Performance Graph

- 9. Key Engineering Considerations

- 10. Final Recommendations

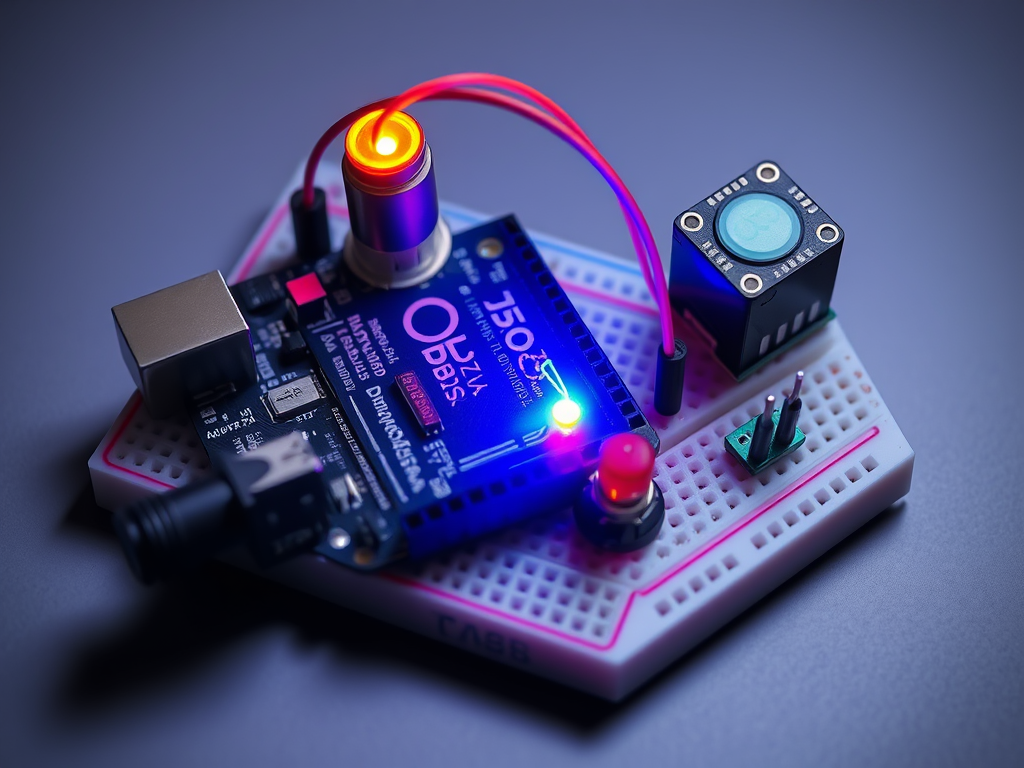

Mastering Robotics: How To Design a Programmable Omni-Directional Robotic Arm Vehicle With Arduino

Designing an omni-directional robotic arm vehicle is one of the most rewarding intermediate-to-advanced Arduino engineering projects. It combines mechatronics, embedded programming, motion control, and system integration—making it an ideal capstone project for robotics learners and hobbyists alike. This guide walks through the complete process: architecture, components, kinematic design, and implementation strategies, supported by diagrams and a conceptual performance graph.

1. Understanding the Project Architecture

A programmable omni-directional robotic arm vehicle integrates two major robotic systems:

- A mobile omni-directional base

- A multi-degree-of-freedom (DOF) manipulator arm

Together, they enable full mobility and articulated motion, allowing the robot to navigate tight spaces and manipulate objects from various angles.

System Overview Diagram

----------------------------------------------------

| Arduino Mega/Uno |

| (Central Control System) |

----------------------------------------------------

| | |

Motor Drivers Servo Controller Sensor Suite

| | |

Omni Base Motors Robotic Arm Servos IMU / Ultrasonic

This architecture separates high-current motor actuation from precision servo control, reducing electrical noise and improving responsiveness.

2. Designing the Omni-Directional Base

Omni-directional movement is accomplished using Mecanum wheels or omni wheels. These wheels allow the vehicle to move:

- Forward/backward

- Sideways

- Diagonally

- Rotate in place

Wheel Configuration

For a four-wheel Mecanum setup:

Front

/ \ / \

/ \ / \

[Wheel] [Wheel]

45° -45°

-45° 45°

[Wheel] [Wheel]

\ / \ /

\ / \ /

Back

Each wheel has rollers angled at 45°, allowing force vectors to combine into omnidirectional motion. Arduino controls each motor through an H-bridge motor driver or a two-channel ESC depending on load requirements.

3. Building the Programmable Robotic Arm

A typical DIY robotic arm includes 4–6 DOF, each controlled by servo motors. Common degrees of freedom include:

- Base rotation (yaw)

- Shoulder lift

- Elbow articulation

- Wrist pitch/rotation

- Gripper open/close

Basic Arm Kinematic Diagram

(Joint 4 - Wrist)

|

|

(Joint 3 - Elbow)

/

/

(Joint 2 - Shoulder)

|

|

(Joint 1 - Base Rotation)

|

Robot Base

Servos are driven either directly by Arduino or by a PCA9685 servo driver for improved stability.

4. Required Components

Electronics

- Arduino Mega or Arduino Uno

- L298N or BTS7960 motor drivers

- PCA9685 16-channel servo controller

- IMU (MPU-6050 or MPU-9250)

- Ultrasonic or LiDAR sensors

- Power distribution module

- 12V Li-ion battery pack + 5V BEC regulator

Mechanical

- Aluminum or acrylic robot chassis

- Four Mecanum wheels with DC gear motors

- Robotic-arm structural kit (or 3D-printed components)

- Ball bearings and mounting brackets

Software

- Arduino IDE

- Robotics libraries (AccelStepper, Adafruit PWM Servo Driver)

- Optional: ROS (Robot Operating System) for advanced control

5. Programming the Omni-Directional Drive System

To achieve smooth omni-directional motion, you must calculate wheel speeds based on joystick or autonomous navigation inputs.

Mecanum Wheel Speed Equations

Let:

- Vx = lateral velocity

- Vy = forward velocity

- ω = rotational velocity

Front Left Wheel = Vy + Vx + ω

Front Right Wheel = Vy - Vx - ω

Rear Left Wheel = Vy - Vx + ω

Rear Right Wheel = Vy + Vx - ω

These values are normalized and mapped to PWM outputs.

6. Programming the Robotic Arm

Servo-based arms use inverse kinematics (IK) to calculate joint angles for a desired end-effector position.

Simple 2-DOF IK Example

For shoulder–elbow positioning:

theta1 = atan2(y, x)

theta2 = acos((x^2 + y^2 - L1^2 - L2^2)/(2 * L1 * L2))

Then convert angles to servo PWM values.

7. Integrating the Systems

Large robotic systems must be integrated carefully:

- Separate power rails for motors and logic

- Grounds tied together for reference

- Buffered communication between control modules

- Modular testing:

- Test drive base first

- Test arm motion

- Combine autonomy or joystick control

Full System Integration Diagram

+-------------------------+

| Arduino Mega |

+-------------------------+

| | |

+----------+ | +----------+

| | |

Motor Driver PCA9685 Servo Sensor Unit

(Mecanum Base) Controller (IMU, Ultrasonic)

| | |

Wheel Motors Arm Servos Navigation Data

8. Example Performance Graph

Below is a conceptual performance visualization showing how payload weight affects arm stability and drive speed.

Payload vs. Performance Graph (ASCII)

Performance (%)

100 |************************

90 |*********************

80 |*******************

70 |****************

60 |*************

50 |**********

40 |*******

30 |*****

20 |***

10 |*

+-----------------------------------

0 200 400 600 (g)

Payload Weight

As payload increases, mobility and stability typically decline; this must be considered when selecting servos and gear ratios.

9. Key Engineering Considerations

- Torque and load balancing: Ensure servos exceed required torque by at least 30%.

- Power management: Use separate regulators for motors and servos.

- Vibration damping: Add rubber mounts to the sensor array.

- Bandwidth planning: For complex robots, consider CAN bus or Serial multiplexer.

- Cooling: Motors under continuous load may require heatsinks.

10. Final Recommendations

For reliable performance:

- Use Arduino Mega for increased I/O capacity.

- Implement closed-loop motor control via encoders for precise base movement.

- Add PID control for arm joints to maintain stable positioning.

- Transition to ROS if you plan to add mapping, path-planning, or computer vision.

An omni-directional robotic arm vehicle is not only a sophisticated robotics build but also a powerful learning platform for embedded systems, control theory, and autonomous navigation. With the architecture, diagrams, and programming principles outlined above, you have a complete blueprint for building and optimizing your own programmable robotic system.