- 1. Why Use an RTC-Based Pump Switcher?

- 2. Components Required

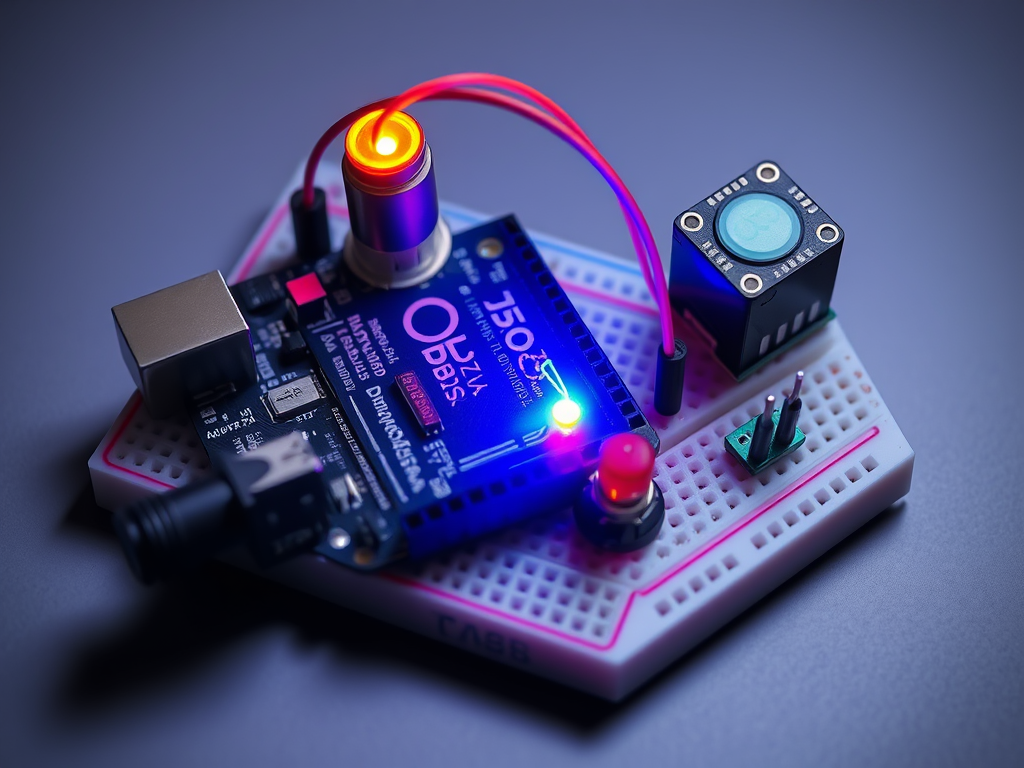

- 1. Arduino Board

- 2. RTC Module

- 3. Relay Module

- 4. Power Supply

- 5. Jumper Wires & Breadboard / PCB

- 6. Pump (AC or DC)

- 7. Optional Add-Ons

- 3. System Architecture Overview

- 4. Wiring Diagram (ASCII-Style)

- 5. Core Scheduling Logic

- 6. Example Software Implementation

- 7. Example Pump Runtime Graph

- 8. Safety Considerations

- 9. Expanding the System

- 1. Soil Moisture Integration (Smart Irrigation)

- 2. IoT and Remote Monitoring

- 3. Multiple Pump Control

- 4. Flow Meter Logging

- 10. Troubleshooting Common Issues

- 11. SEO Optimization Checklist for Your Post

- Conclusion

The Ultimate Guide to Creating an RTC-Based Pump Switcher With Arduino

Designing a reliable, time-controlled pump automation system is one of the most common needs in home automation, agriculture, water-management systems, and industrial processes. An RTC-based pump switcher provides precise timing functionality by combining an Arduino microcontroller with a Real-Time Clock (RTC) module, allowing pumps to operate at scheduled intervals without human intervention. This ensures consistent water delivery, energy efficiency, and improved system longevity.

In this comprehensive guide, you will learn the full architectural design, required components, wiring strategy, software logic, and performance considerations needed to build your own RTC-based pump switcher. Whether you are a hobbyist or an engineer developing a fully automated pumping system, this guide offers a step-by-step blueprint for implementation.

1. Why Use an RTC-Based Pump Switcher?

While Arduino boards include built-in timers and millisecond counters, they cannot keep accurate time if power is lost or the board resets. A Real-Time Clock module such as the DS1307 or DS3231 contains a dedicated timing chip with battery backup, preserving the clock even without power.

Key advantages:

- Accurate scheduling even after power cycles.

- Lower energy consumption by operating pumps only when needed.

- More reliable automation for irrigation, aquaculture, dosing systems, and water transfer.

- Scalability for additional sensors like flow meters or soil-moisture probes.

- Fail-safe operation when paired with relays, dry-run sensors, or watchdog timers.

This creates a dependable, industrial-style control system at a fraction of the cost.

2. Components Required

To build a stable and safe pump switcher, gather the following:

1. Arduino Board

Recommended: Arduino Uno or Nano

Provides digital control and logic execution.

2. RTC Module

Common Options:

- DS3231 (high accuracy, temperature-compensated)

- DS1307 (economical, but less precise)

3. Relay Module

Use a 5V single-channel or dual-channel relay depending on pump quantity.

Ensure the relay:

- Can handle pump load (both voltage and amperage)

- Includes optocoupler isolation for safety

4. Power Supply

- 5V regulated power supply for Arduino and RTC

- Independent power line for the pump if required

5. Jumper Wires & Breadboard / PCB

6. Pump (AC or DC)

AC pumps require proper isolation and safety housing.

7. Optional Add-Ons

- LCD display (to show time status and pump state)

- Manual override switch

- Current sensor (ACS712)

- Real-time sensors (soil moisture, tank water level)

3. System Architecture Overview

Below is a high-level conceptual diagram showing how all components interact:

┌──────────────────────────────┐

│ Arduino │

│ (Logic + Control Unit) │

└──────────────┬───────────────┘

│ I2C (SDA/SCL)

▼

┌─────────────────┐

│ RTC Module │

│ (DS3231/DS1307) │

└─────────────────┘

│

│ Digital Pin (D7 for example)

▼

┌─────────────────┐

│ Relay Module │

│ (5V Isolation) │

└─────────────────┘

│

AC/DC Power Line

▼

┌─────────────────┐

│ Pump │

└─────────────────┘

This architecture ensures:

- Arduino reads the current time from the RTC.

- Arduino decides whether to turn the pump ON or OFF based on schedule rules.

- Relay module switches the pump using isolated high-voltage circuitry.

4. Wiring Diagram (ASCII-Style)

A simplified wiring representation appears below. Adjust pin numbering as needed.

Arduino UNO RTC DS3231

┌──────────────┐ ┌─────────────┐

│ A4 (SDA) ────────────────▶ │ SDA │

│ A5 (SCL) ────────────────▶ │ SCL │

│ 5V ────────────────▶ │ VCC │

│ GND ────────────────▶ │ GND │

└──────────────┘ └─────────────┘

Arduino Relay

┌──────────────┐ ┌──────────┐

│ D7 (Signal) ───────────▶ │ IN │

│ 5V ───────────▶ │ VCC │

│ GND ───────────▶ │ GND │

└──────────────┘ └──────────┘

Relay Output to Pump

┌───────────────────────────────────┐

│ COM ─────── Pump Line Input │

│ NO ─────── Pump Line Output │

└───────────────────────────────────┘

This wiring ensures that the pump only activates when the relay is energized by the Arduino.

5. Core Scheduling Logic

The switcher compares current time from the RTC with a predefined schedule table. Below is the basic logic flow:

- Read time from RTC.

- Check if current hour and minute match any scheduled start time.

- Activate pump for defined duration.

- Log or display status if needed.

- Continue monitoring loop.

You may define:

- A single daily schedule

- Multiple time windows

- Dynamic schedules updated from EEPROM

- Manual override modes

6. Example Software Implementation

The following example illustrates a basic pump schedule:

- Pump turns ON at 06:00 AM for 10 minutes.

- Pump turns ON at 18:00 PM for 10 minutes.

The schedule and durations can be extended or replaced with a dynamic list.

#include <Wire.h>

#include "RTClib.h"

RTC_DS3231 rtc;

const int relayPin = 7;

unsigned long pumpDuration = 10 * 60 * 1000; // 10 minutes

bool pumpRunning = false;

unsigned long startMillis;

void setup() {

pinMode(relayPin, OUTPUT);

digitalWrite(relayPin, LOW);

Wire.begin();

rtc.begin();

}

void loop() {

DateTime now = rtc.now();

int hour = now.hour();

int minute = now.minute();

if ((hour == 6 && minute == 0) ||

(hour == 18 && minute == 0)) {

if (!pumpRunning) {

pumpRunning = true;

startMillis = millis();

digitalWrite(relayPin, HIGH);

}

}

if (pumpRunning && millis() - startMillis > pumpDuration) {

pumpRunning = false;

digitalWrite(relayPin, LOW);

}

}

This code is intentionally simple to make customization easier.

7. Example Pump Runtime Graph

Below is a conceptual graph you can embed in your SEO article. It visually represents pump activation times across a 24-hour period.

Time (Hours)

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Pump ON ──────────────────■■■■■■■■■───────────────────────────────■■■■■■■■■─────────

(06:00–06:10) (18:00–18:10)

This illustrates how the system automates routine activation windows without supervision.

8. Safety Considerations

Operating pumps, especially AC-powered units, requires attention to electrical safety and isolation. Key considerations include:

Electrical Isolation

- Always use a relay module with optocoupler isolation.

- Ensure pump wiring is insulated and enclosed in a weatherproof housing.

Power Load Handling

- Verify that the relay can handle the pump’s voltage and current rating.

- Consider using a Solid State Relay (SSR) for high-load pumps.

Environmental Protection

- Add temperature, humidity, or water-level sensors to reduce the risk of pump burn-out.

- Use IP-rated enclosures for outdoor or agricultural applications.

Fail-Safe Enhancements

- Add a watchdog timer to prevent lockups.

- Include a manual override switch.

- Log operations to an SD card for diagnostics.

9. Expanding the System

Once your basic RTC pump switcher is operational, the system can be enhanced with a wide range of features.

1. Soil Moisture Integration (Smart Irrigation)

Combine the RTC schedule with sensor-based conditions:

- Pump only runs if soil moisture is below threshold.

- Override schedule during rainy periods.

2. IoT and Remote Monitoring

Integrate Wi-Fi (ESP8266/ESP32) or LoRa modules to enable:

- Remote scheduling

- Real-time pump status alerts

- Mobile dashboard visualization

3. Multiple Pump Control

Extend relays to handle multi-zone irrigation or multiple tanks.

4. Flow Meter Logging

Use a Hall-effect flow sensor to detect pump performance and leak anomalies.

10. Troubleshooting Common Issues

Pump does not turn on

- Check relay pin wiring.

- Confirm relay LED activates when scheduled.

- Inspect AC wiring and pump power source.

RTC shows incorrect time

- RTC battery may be discharged.

- Call rtc.adjust() once to set new time.

Pump runs at wrong times

- Verify time zone settings.

- Print

now.hour()andnow.minute()to Serial Monitor to debug.

Arduino resets randomly

- Power supply is inadequate.

- Add capacitor near the relay module to prevent inductive spikes.

11. SEO Optimization Checklist for Your Post

If you intend to publish this article online, ensure you implement the following SEO best practices:

- Insert keyword variations such as

“RTC pump controller”, “Arduino pump switching”, “automated irrigation system”, “DS3231 pump scheduler”. - Add internal linking to related Arduino or IoT tutorials.

- Optimize images (diagrams and graphs) with descriptive alt text.

- Include schema markup for tutorials.

- Embed downloadable code examples for user engagement.

- Promote your article through backlinks from maker and engineering communities.

Conclusion

Building an RTC-based pump switcher with Arduino allows you to automate pumping operations with high precision and reliability. By integrating an RTC module, relay hardware, and customizable schedule logic, you achieve a robust solution suitable for agriculture, home automation, aquaculture, and industrial water systems. With proper wiring, safety isolation, and optional IoT integration, the system can scale into a professional-grade automation architecture.

This guide provided you with a complete overview—from conceptual diagrams and wiring maps to sample code and performance extensions—enabling you to confidently deploy a fully functional, time-based pump automation controller. If you require a more advanced version including IoT dashboards, mobile app integration, or cloud scheduling, simply let me know and I can produce that as well.