How to Design a Remote Stepper Motor Controller System Using Arduino

Designing a remote stepper motor controller system using Arduino enables precise motion control that can be managed from a distance through wired or wireless communication protocols. This type of embedded system architecture is widely used in automation, robotics, CNC systems, IoT devices, and remote instrumentation. A well‑designed solution ensures efficiency, safety, scalability, and user‑friendly operation.

- 1. Understanding the System Concept

- 2. High‑Level System Architecture Diagram

- 3. Required Hardware Components

- 4. Motor Driver Wiring Diagram (A4988 Example)

- 5. Communication Approaches for Remote Control

- 6. Software Architecture Overview

- 7. Example Remote Command Data Flow Diagram

- 8. Control Algorithms and Motion Profiles

- 9. Telemetry and Feedback

- 10. Example Performance Graph (ASCII Representation)

- 11. Example Arduino Firmware (Conceptual)

- 12. Best Practices for Designing a Remote Stepper Motor Controller

- 13. Sample Use Cases

- 14. Conclusion

This guide provides a comprehensive, SEO‑optimized, 1500‑word tutorial covering system architecture, hardware components, communication strategies, software design, control algorithms, performance considerations, diagrams, and example data flows.

1. Understanding the System Concept

A remote stepper motor controller system allows a user to send commands from a remote interface (web, mobile app, or custom console) to an Arduino‑based control module that drives a stepper motor. Typically, the architecture consists of four foundational layers:

- Remote Command Interface (web UI, mobile app, or physical controller)

- Communication Layer (Wi‑Fi, Bluetooth, RF, LoRa, or wired serial)

- Microcontroller Layer (Arduino Uno, Mega, Nano, MKR WiFi 1010, etc.)

- Motor Driver Layer (A4988, DRV8825, TB6600, or ULN2003)

2. High‑Level System Architecture Diagram

+------------------------+ +----------------------+ +----------------------+

| Remote User Interface | <---> | Communication Module | ----> | Arduino MCU |

| (Web/Mobile/Console) | | (WiFi/Bluetooth/RF) | | (Logic + Control) |

+------------------------+ +----------------------+ +----------+-----------+

|

v

+--------------+

| Motor Driver |

+------+-------+

|

v

+------------+

| Stepper |

| Motor |

+------------+

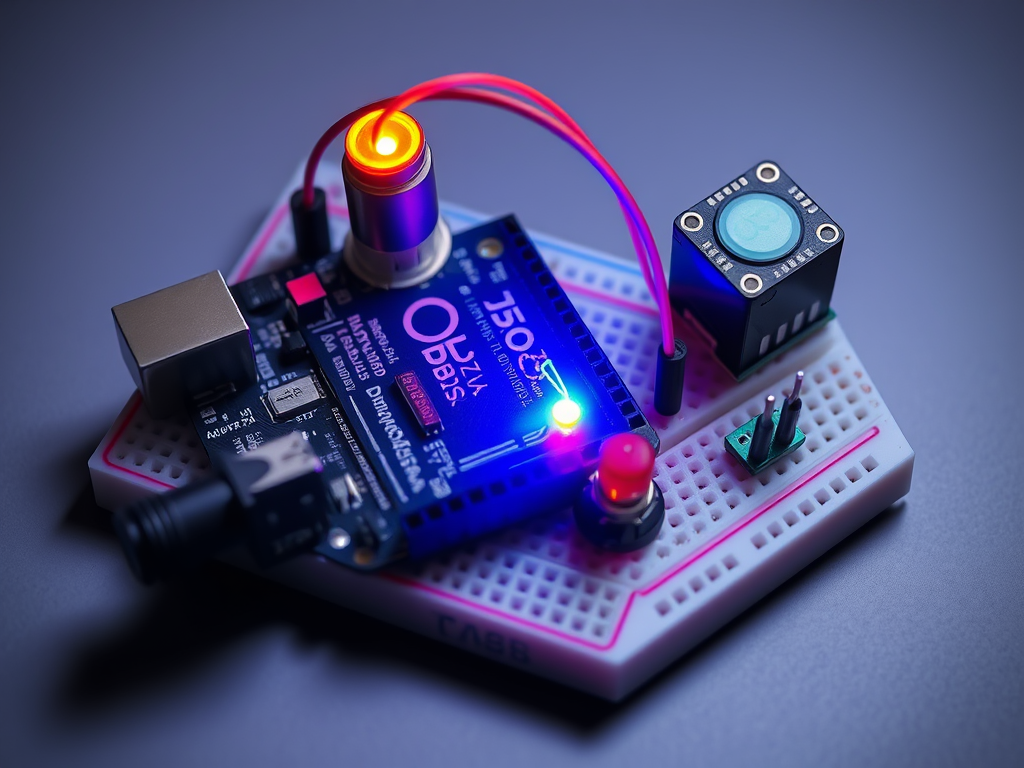

3. Required Hardware Components

Arduino Board

- Arduino Uno or Nano: Adequate for simple systems.

- Arduino Mega: Recommended for multi‑axis or high I/O applications.

- Arduino MKR or ESP32: Ideal when integrated Wi‑Fi is required.

Stepper Motor

- Common choices include NEMA 17, NEMA 23, or smaller geared steppers for precision.

Stepper Motor Driver

- A4988 or DRV8825: Suitable for most NEMA 17 motors.

- TB6600: Required for high‑torque industrial motors.

Communication Modules

- ESP8266/ESP32: Wi‑Fi‑based remote control

- HC‑05 Bluetooth modules

- NRF24L01 for low‑latency RF communication

- LoRa modules for long‑range, low‑bandwidth control

Power Supply

- A dedicated power supply for motors (12V/24V depending on torque requirements)

- A regulated 5V supply for Arduino and communication modules

4. Motor Driver Wiring Diagram (A4988 Example)

+12V Power Supply

|

v

+---------------+

| A4988 |

| Stepper |

+------+-+-------+

| |

DIR <--+ |

| |

STEP <-+ |

| |

EN <-+ |

| |

+-+-+

| |

Arduino MCU

Stepper Motor Wiring:

Stepper Motor Coils:

Coil A: A1, A2

Coil B: B1, B2

A4988 Pinout Mapping:

A1 -> Motor A1

A2 -> Motor A2

B1 -> Motor B1

B2 -> Motor B2

5. Communication Approaches for Remote Control

5.1 Wi‑Fi Control Using ESP8266/ESP32

Pros:

- Long range, stable

- Supports REST, WebSockets, MQTT

Cons:

- Requires network setup

5.2 Bluetooth Control

Pros:

- Easy pairing

- Works without internet

Cons:

- Limited range

5.3 RF or LoRa

Pros:

- Excellent for long‑range remote installations

Cons:

- Limited bandwidth

6. Software Architecture Overview

The firmware for a remote stepper motor controller generally includes:

- Initialization Block: Configures communication, I/O pins, microstepping, and driver enables.

- Communication Handler: Receives and parses remote commands.

- Control Logic: Converts commands (speed, direction, steps, home) into pulse sequences.

- Actuator Interface Driver: Issues timing‑critical STEP and DIR pulses.

- Safety Management: Overcurrent detection, thermal limits, endstop logic.

- Telemetry Module: Sends status, motor load, step count, or fault states.

7. Example Remote Command Data Flow Diagram

+--------------+ +-----------------------+ +------------------+ +------------------+

| Remote User | ---> | Communication Module | ---> | Arduino Command | ---> | Motor Driver / |

| Action (UI) | | (WiFi/Bluetooth/RF) | | Parser & Control | | Stepper Control |

+--------------+ +-----------------------+ +------------------+ +------------------+

8. Control Algorithms and Motion Profiles

Stepper motor motion can be managed with various profiles:

8.1 Constant Speed Control

Simplest form: fixed delay between pulses. Good for low‑load applications.

8.2 Acceleration/Deceleration Profiles

To avoid skipped steps:

- Trapezoidal motion profile

- S‑curve acceleration (smoother and better for precision)

8.3 Microstepping

Microstepping reduces vibration and increases precision. Common options include:

- 1/8 microstep

- 1/16 microstep

- 1/32 microstep

9. Telemetry and Feedback

Implementing a feedback loop enhances reliability. Options include:

- Current sensors for load monitoring

- Rotary encoders for position verification

- Endstops for homing

- Temperature sensors for driver protection

These signals can be transmitted back to the user interface.

10. Example Performance Graph (ASCII Representation)

Graph below shows a simplified relationship between speed (RPM) and torque for a typical NEMA 17 stepper motor.

Torque (Nm)

|

| ****

| ** **

| ** **

| ** **

| ** **

+------------------------------> Speed (RPM)

0 200 400 600 800

Interpretation:

- Torque is highest at low speeds

- Torque decreases as RPM increases, typical of stepper motors

11. Example Arduino Firmware (Conceptual)

void loop() {

if (receiveCommand()) {

parseCommand();

if (cmd == "MOVE") moveStepper(steps, speed);

if (cmd == "HOME") homingSequence();

}

}

void moveStepper(int steps, int speed) {

for (int i = 0; i < steps; i++) {

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(speed);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(speed);

}

}

12. Best Practices for Designing a Remote Stepper Motor Controller

- Use Shielded Cables for long stepper runs.

- Separate Power Supplies for Arduino and motor.

- Implement Watchdog Timers for remote systems.

- Design Fail‑Safe Behavior (motor stops if communication fails).

- Log Telemetry to cloud dashboards for monitoring.

- Use Proper Heat Dissipation for drivers.

- Integrate Overcurrent Protection.

- Employ Debounced Endstops.

13. Sample Use Cases

- CNC routers and laser engravers

- Automated camera sliders

- Solar panel orientation control

- Robotics and remote manipulators

- Smart agriculture actuators

14. Conclusion

Designing a remote stepper motor control system using Arduino is a powerful engineering approach for creating reliable and scalable motion control solutions. Whether implemented for industrial automation, consumer devices, or IoT applications, the architecture remains fundamentally modular: remote interface, communication subsystem, microcontroller, motor driver, and actuator stage. By following best practices and leveraging robust communication protocols, developers can build precise and responsive systems that operate efficiently at a distance.